The automotive industry is competing with other markets for a crucial piece of technology which cannot easily be sourced, the semiconductor. The shortage of semiconductors has led to vehicle production shutdowns and delayed deliveries, impacting registrations and financial results. But what are semiconductors, why are they important and how big a problem is the shortage of supply? Autovista24 editor Phil Curry explains all in the latest What is? video.

The semiconductor problem

Car manufacturers are increasing the amount of technology in their vehicles, and this means greater use of semiconductor chips. Cars can have up to 4,000 chips inside, premium vehicles featuring more than budget cars. Semiconductor chips can be found in everything from powertrain options to chassis-handling controls, infotainment, safety and security systems and comfort options.

During the COVID-19 pandemic carmakers reducing their supply of chips on the back of less vehicle demand, while the demand for consumer electronics goods increased. With people staying at home.

This meant that as vehicle manufacturers increased their production capabilities again, there were not enough semiconductor chips available. This has led to 18 months of delayed vehicle deliveries, impacting registrations of new vehicles and financial performance.

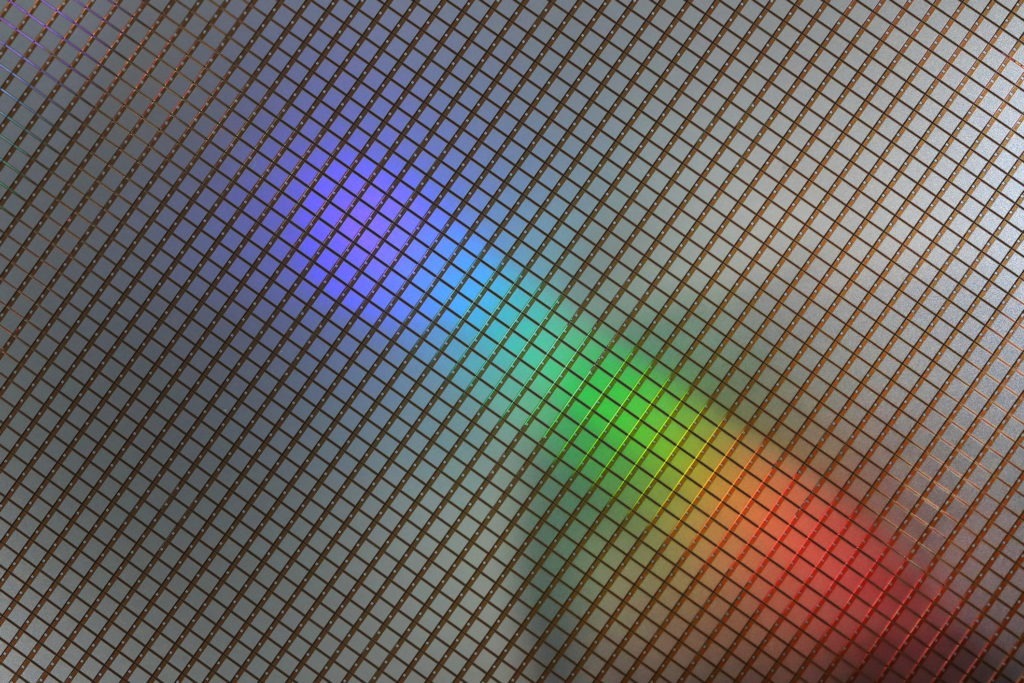

The problem is the complexity of the semiconductor chip. They are manufactured using extremely rigorous and complex methods. They require large factories, dust-free rooms and carefully controlled atmospheres. The etching and layering of the chips is very time consuming, meaning overall, a single microchip can take three months to produce

The automotive industry is finding ways to reduce reliance on semiconductor chips while supply levels increase. Carmakers are prioritising markets, reducing the number of available technological optional extras and sharing systems more between models. The chip-supply shortage could last for the rest of the year. However, companies are slowing investing in new production facilities, although these may take some time to become operational, as building new factories is time-consuming.

The semiconductor and the chip

A semiconductor is a material with properties between a conductor and an insulator. It is usually a solid chemical element or compound that conducts electricity under certain conditions but not others, making it ideal to control current, and therefore electronic appliances.

A good example of a semiconductor material is silicone with controlled impurities added. This is called ‘doped’ silicone, and depending on additives, the number of electrons can be increased or lowered, giving different conductive effects.

Semiconductors are an important component when creating integrated circuits, also known as chips or microchips. Many people will interchange the terms, but the semiconductor is the material, while the chip is the electronic part that controls systems.

Integrated circuits are built from a number of microscopic circuits, transistors, diodes and wiring fabricated on top of a semiconductor. These parts work together to handle the processing tasks of most electrical components. These chips can replace many larger circuits, with the semiconductor regulating energy flow. This means the chips can be made smaller, and more powerful.

Close

Close